English

English Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  שפה עברית

שפה עברית  Cymraeg

Cymraeg  Galego

Galego  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Yoruba

Yoruba  অসমীয়া

অসমীয়া  ଓଡିଆ

ଓଡିଆ  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

Industrial Waste Gas VOC Treatment Equipment

Industrial waste gas VOC treatment equipment can effectively manage and mitigate volatile organic compounds (VOCs) emitted from various industrial processes. The equipment is designed to capture, treat and neutralize harmful gases, ensuring compliance with strict environmental regulations while promoting a cleaner and safer workplace.

Send Inquiry

Industrial waste gas VOC treatment equipment uses advanced technologies such as adsorption, condensation and catalytic oxidation, which work together to significantly reduce the concentration of VOCs in the waste gas. By integrating these technologies, the equipment can not only minimize environmental impact, but also improve operational efficiency, making it an important investment in industries such as manufacturing, chemical processing and refining.

- Industrial waste gas often contains volatile organic compounds (VOCs), which pose risks to the environment and health.

- Effective treatment of VOCs is essential to comply with environmental regulations and minimize air pollution.

- There are a variety of technologies available for VOC treatment, including adsorption, absorption and thermal oxidation.

- Adsorption systems use materials such as activated carbon to capture VOCs from the waste gas stream.

- Absorption methods involve transferring VOCs from the gas phase to the liquid phase, usually using solvents.

- The thermal oxidation process burns VOCs at high temperatures, converting them into less harmful substances.

- The choice of treatment technology depends on factors such as VOC concentration, flow rate, and specific regulatory requirements.

- Regular maintenance and monitoring of VOC treatment equipment is essential to achieve optimal performance and efficiency.

- Technological advances continue to improve the effectiveness and cost-effectiveness of VOC treatment solutions.

Industrial waste gas VOC treatment equipment emphasizes sustainability and cost-effectiveness. By effectively reducing VOC emissions, companies can avoid huge fines associated with non-compliance and contribute to a healthier environment. The energy-saving design of the system reduces operating costs because it requires less energy to operate than traditional treatment methods. In addition, the treated gas can often be reused or safely discharged into the atmosphere, further enhancing the overall sustainability of industrial operations. Investing in industrial waste gas VOC treatment equipment not only meets corporate social responsibility goals, but also enables companies to become leaders in environmental management within their respective industries.

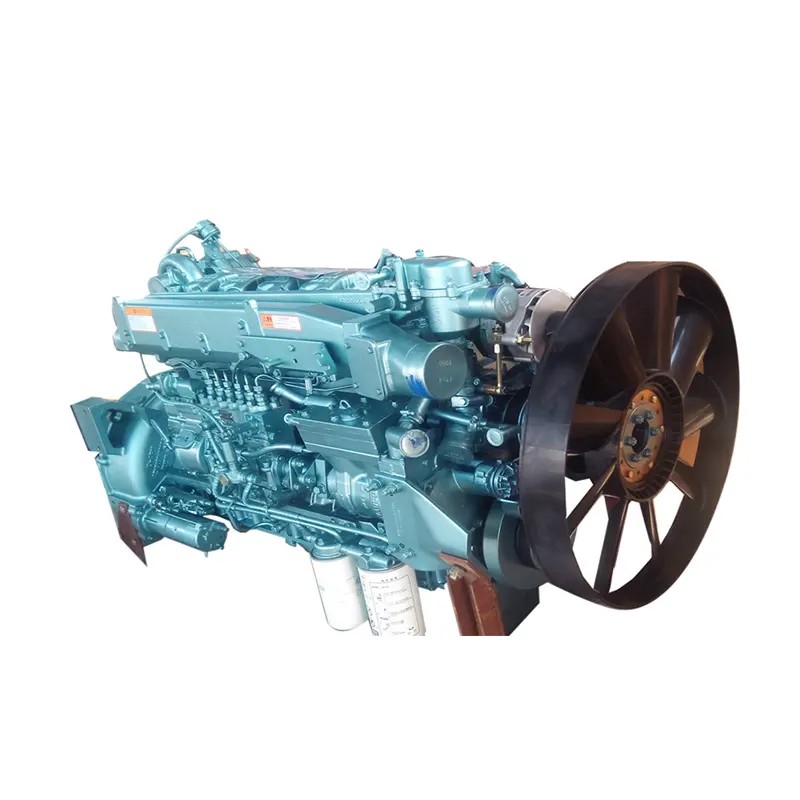

Core Components:Gear, Engine, Motor

Place of Origin:Jinan, China

Warranty:1 Year

Weight (KG):30000 kg

Condition:New

Purify Efficiency:99%

Application:Industry Gas Filter

Function:Removing High Concentration Exhaust Gas

Usage:Air Purification System

Specification of Industrial Waste Gas VOC Treatment Equipment

| Feature | High Efficiency |

| Application | Industry |

| Usage | Air Purification System |

FAQ

Q1: How about the quality of your products?

A1: Our products have passed ISO9001certification, the technology has reached the international advanced level, and the products are energy-saving, efficient, stable and environmentally friendly.

Q2: Can the product be customized?

A2: Yes, we have a professional design and calculation team to customize products to meet your needs for different customers.

Q3: What are your products used in?

A3: Our products can be used in petroleum, chemical, painting, tobacco, light industry, agriculture, food, medicine,

environmental protection and many other industries, used in a variety of incinerators, emission process flue gas and other need waste heat recovery, waste gas recovery, energy conservation and environmental protection in the field of gas and gas heat exchange.

Q4: How long will it take for delivery after placing an order?

A4: The delivery time is 30-45 days depending on the product ordered by the customer.

Q5: Can I get a lower price for ordering more products?

A5: Yes, the price can be discounted.