English

English Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  שפה עברית

שפה עברית  Cymraeg

Cymraeg  Galego

Galego  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Yoruba

Yoruba  অসমীয়া

অসমীয়া  ଓଡିଆ

ଓଡିଆ  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

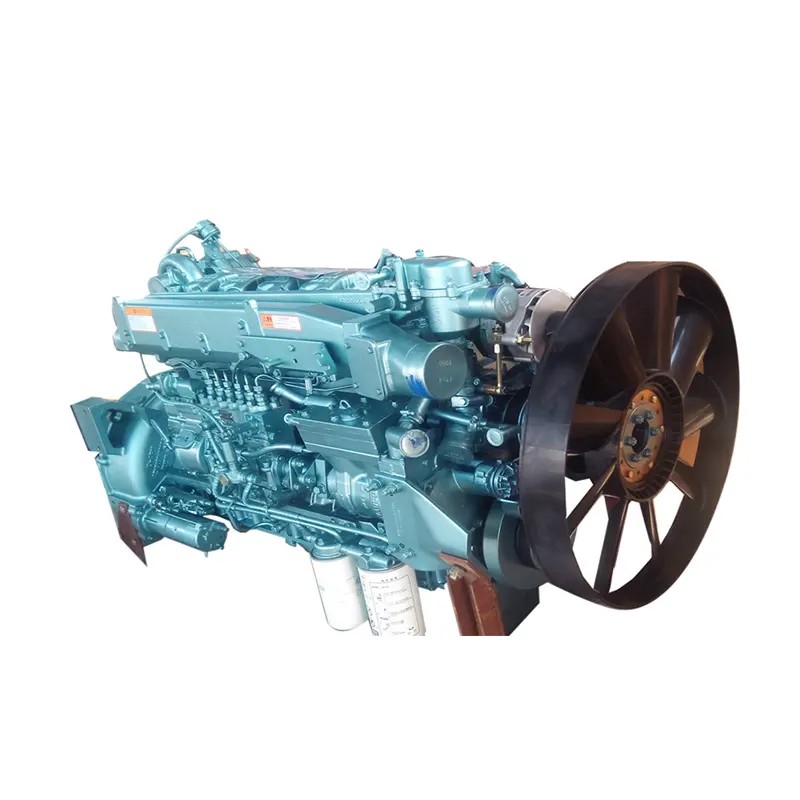

Pusher Machine

Shandong Lano is a professional manufacturer of Pusher Machines. Pusher Machines have revolutionized material handling, improving efficiency while eliminating the need for manual labor. Pusher Machine are common in various industries such as logistics, manufacturing and food processing, and have become an integral part of the production line.

What is a Pusher Machine?

A pusher is a device that pushes materials to the next station of the production line, streamlining the manufacturing process. It mainly consists of parts such as the propulsion system, hydraulic system, operating system and frame. It is a cost-effective and space-saving solution that provides maximum efficiency with minimal maintenance. Pusher Machines can handle a variety of materials, including butter, cheese and even bricks.

How does a Pusher Machine work?

The working principle of a Pusher Machine is based on the hydraulic system to provide power. After the hydraulic pump pressurizes the oil, it drives the pusher forward through the hydraulic motor to achieve the advancement of the material. The propulsion system is the core part of the Pusher Machine, which consists of components such as the pusher, connecting rod, slide plate and slider. When the pusher moves forward, the connecting rod transmits power to the slide plate, which slides inside the slider, thereby pushing the material forward. Pushers are equipped with conveyor belts to move materials along the production line. The Pusher Machine is placed next to the conveyor and uses hydraulic pressure to push the material to the next station. It operates accurately and quickly, reducing any delays in the production process.

- View as

Coke Separator for Coking Industry

As the professional manufacturer, Lano would like to provide you Coke Separator for Coking Industry. The Coke Separator is designed to be highly efficient and reliable. It can operate continuously for long periods of time without experiencing any significant downtime or maintenance issues.

Read MoreSend InquiryPusher Machine for Coking Plant

The High-quality Pusher Machine for Coking Plant from Lano is responsible for pushing the coke out of the furnace after carbonization, ensuring efficient handling and transfer of the material. The machine plays a vital role in the production of coke, which is essential to the steel manufacturing process.

Read MoreSend Inquiry