English

English Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  שפה עברית

שפה עברית  Cymraeg

Cymraeg  Galego

Galego  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Yoruba

Yoruba  অসমীয়া

অসমীয়া  ଓଡିଆ

ଓଡିଆ  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

Pusher Machine for Coking Plant

High-quality Pusher Machine for Coking Plant is responsible for pushing the coke out of the furnace after carbonization, ensuring efficient handling and transfer of the material. The machine plays a vital role in the production of coke, which is essential to the steel manufacturing process.

Send Inquiry

Pusher Machine for Coking Plant is an important piece of equipment that improves the efficiency and productivity of coke operations. The pusher is an integral part of the coking process, which helps improve operational efficiency and the quality of the end product, while also highlighting the need for continuous innovation and maintenance in coke plant operations. This rugged machine is designed to handle the demanding environment of a coke plant, where high temperatures and heavy loads are common. Its primary function is to push the coke from the furnace into the quenching zone, ensuring a seamless transition that minimizes downtime and maximizes production. Made of high-quality materials, the coke pusher can withstand the rigors of continuous operation, providing reliability and longevity in challenging industrial environments.

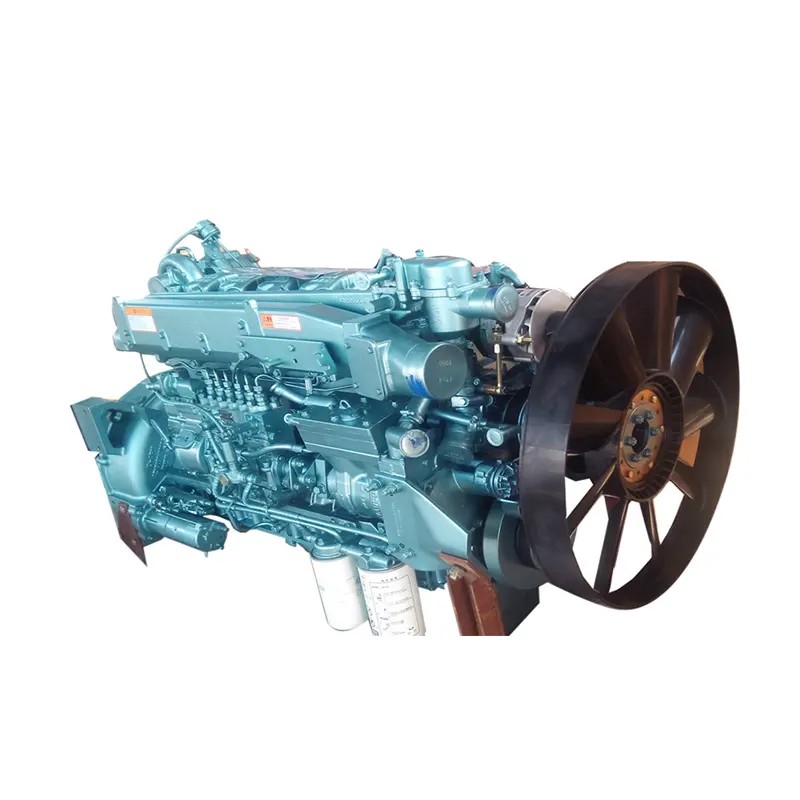

Core Components: PLC, Engine, Pressure vessel

Weight (T):50 T

Power (kW):100000

Warranty:1 year

Use"Heat Treatment Furnace

Brand Name: Lano

Voltage:250

Dimension(L*W*H):180*1.2*3.4m

Key Selling Points:Low Noise Level

After-sales Service:Provided Overseas third-party support available

Product Name:Rotary kiln repaired and building

Working Temperature:1180-1250

Feature:Energy-saving

Capacity: 10kg~50ton

Heating rate:85%

The Pusher Machine for Coking Plant is simple to maintain, thanks to its modular design that allows easy access to key components. A regular maintenance schedule can be easily implemented, ensuring the machine operates at peak efficiency and reducing the likelihood of unexpected failures. Combining durability, advanced technology and easy maintenance, the coke pusher is an important tool for improving operational efficiency and productivity in the coke industry.

Evaluation and preparation of refractory materials

Rotary kiln is very common in the refractory industry. Common uses include calcined clay, high alumina bauxite, magnesia, high iron sand, magnesia chrome sand, magnesium aluminum spinel, dolomite and activated lime.

Recommended by LITE The calcined belt is lined with corundum mullite bricks, and the outer layer is light mullite brick. The top of the preheater is made of hanging bricks, and the rest is made of refractory castable. The brick type is small and the masonry is simple.

Acceptance and trial

1.Whether the expansion joint is filled with insulation material, and whether the closed hole should be closed tightly;

2.Whether the sand sealing groove is added to the sand according to the regulations;

3.Whether the mechanical kiln door and the damper lift are flexible, and whether the closing is tight and airtight.

| Kiln name | Size |

Width (m) |

Firing temperature (℃) |

Firing cycle (hour) |

Fuel consumption (kcal/kg) |

Annual production |

|

Metallurgical powder tunnel kiln |

110- 220m |

1.85-3.5 | 1080-1180 | 50-60 | 1300-1400 |

8000- 50000t |

|

Refractory tunnel kiln |

60- 180m |

1.2-3.4 | 1150-1750 | 40-200 | 1000-1800 |

5000- 30000t |

|

Sanitary porcelain tunnel kiln |

20- 150m |

0.85-4.0 |

1150-1280 |

11-16 |

1200-1500 3000-6000 |

100000- 1200000 pieces |

|

Daily porcelain tunnel kiln |

40- 110m |

1.0-3.0 | 1260-1420 | 14-25 |

1800-2500 4000-5000 |

2000000- 15000000 pieces |

|

Building brick tunnel kiln |

60- 160m |

3.9-6.9 |

1050-1250 |

16-56 |

450-800 650-900 |

20000000- 80000000 pieces |

|

Electric porcelain tunnel kiln |

40- 120m |

1.5-2.5 | 1080-1250 | 50-80 | 5000-6000 | |

|

Other products high temperature tunnel kiln |

40- 110m |

1.3-3.0 | 1300-1700 | 45-70 | 3500-7000 |

According to specific products |

|

Round shaft kiln |

60- 350m³ |

2-4.5m | 950-1500 |

1000-1800kal/kg Ash,magnesia, cement clinker |

16000- 105000t |

|

| Square shaft kiln |

120- 500m³ |

3-6m |

950-1500 |

1000-1800kal/kg Ash,magnesia, cement clinker |

30000- 150000t |

|

|

Architectura decorative porcelain roller kiln |

80- 220m |

0.9-3.5 |

1050-1250 |

0.5-1.5 |

400-700 900-1200 |

100000- 3000000m² |

FAQ

Q1.Can we visit your company?

A:Sure,welcome at any time,seeing is believing.

Q2. Do you provide samples?

A:Yes, samples are available.

Q3. Do you accept OEM?

A:Yes, we can do OEM.

Q4.What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q5.What are the payment terms?

A:Usually T/T,but L/C,Western Union etc are available for us.

Q6. How long is delivery time?

A:The delivery time will be determined according to the quantity of the order.

Q7.How are your products' quality?

A:The products will be strictly inspected before shipment, so the quality could be guaranteed.

Q8.How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make